IGBT is a compound fully controlled voltage-driven power semiconductor device composed of BJT bipolar triode and insulated gate FET MOS.

IGBT is the core device of energy conversion and transmission, commonly known as the "CPU" of power electronic devices, and is widely used in rail transit, smart grid, aerospace, electric vehicles and new energy equipment and other fields.

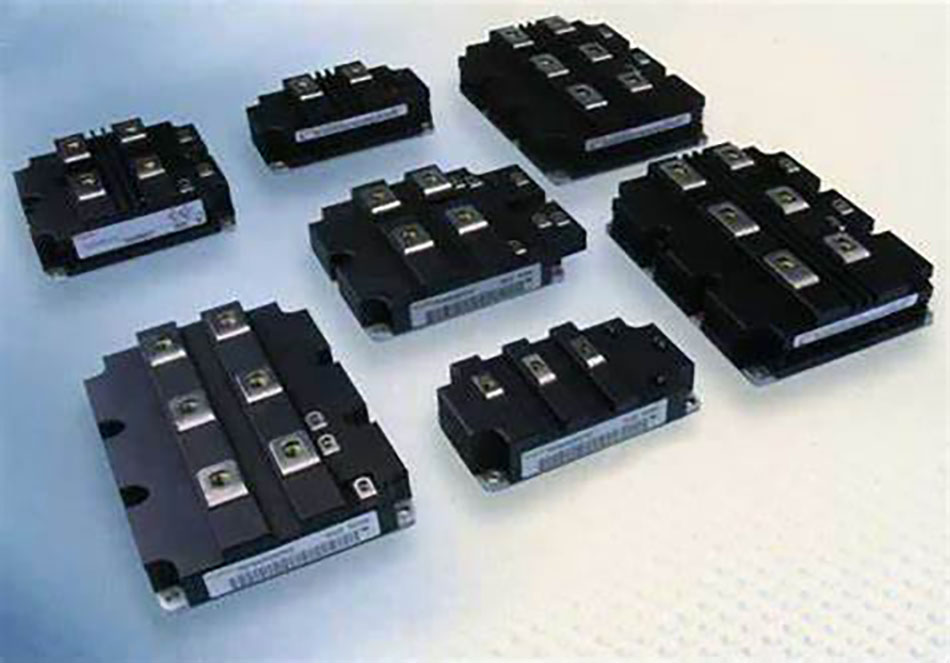

The application of IGBT module determines that it should not only have high reliability, but also have a long service life.

In the process of current switching, IGBT will produce a large power loss, so "heat dissipation" is an important factor affecting its reliability. The chip welding and substrate welding are the main heat transfer channels of IGBT, and the welding quality of the welding affects the reliability and life of IGBT.

The results show that the chip junction temperature increases when there is a void in the solder layer, and the chip junction temperature is almost proportional to the void rate of the solder layer. Therefore, the thermal cycle is affected, the local temperature is too high, and the service life of the module is reduced. When the operating temperature of the device is increased by 10℃, the failure rate will be doubled.

Therefore, the most important thing for IBGT packaging is to reduce the cavity rate of the solder layer.

Zhongshi research and development IGBT preformed solder

Domestic initiative

> IGBT 8-element alloy weld

Product features:

Meet the demand for high reliability and long life of new energy vehicles

- - Longer product life cycle

> IGBT enhanced contour weld

Product features:

- High strength

- Stress distribution is uniform

- Uniform welding layer, welding height controllable

- Low cavity rate

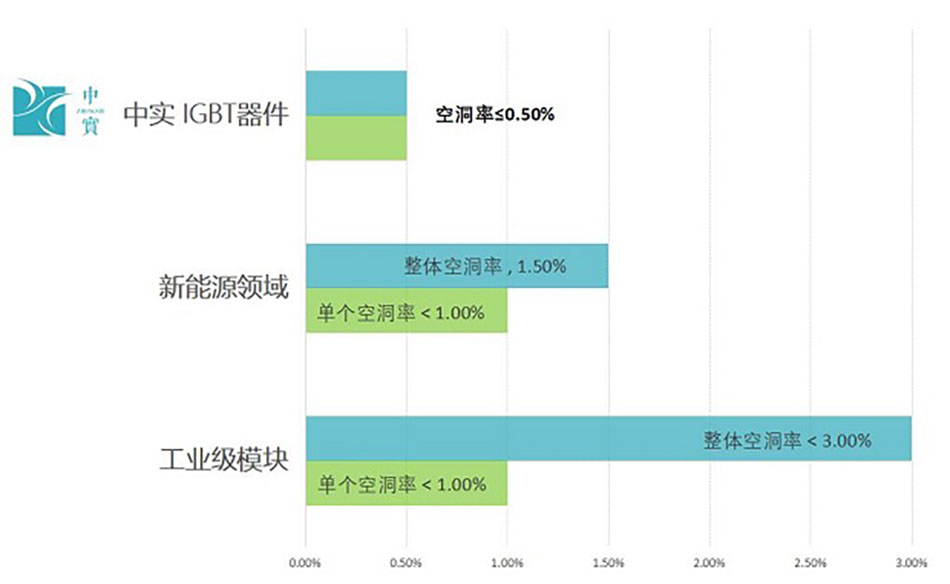

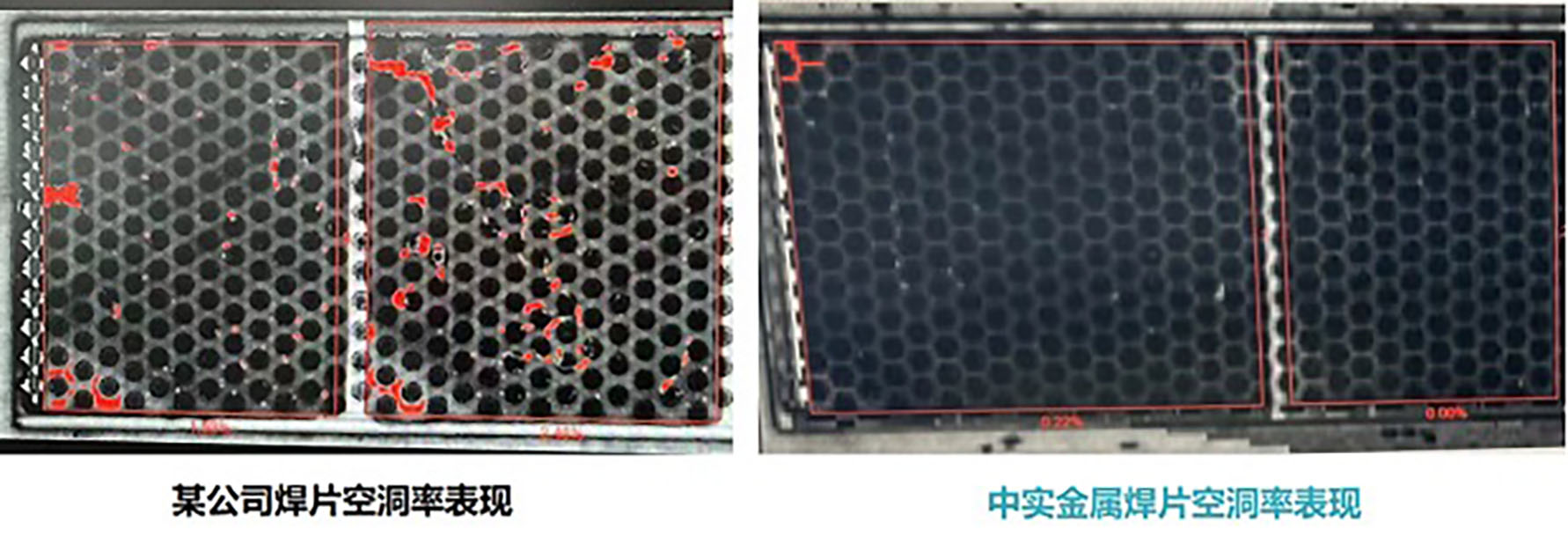

Cavity ratio comparison

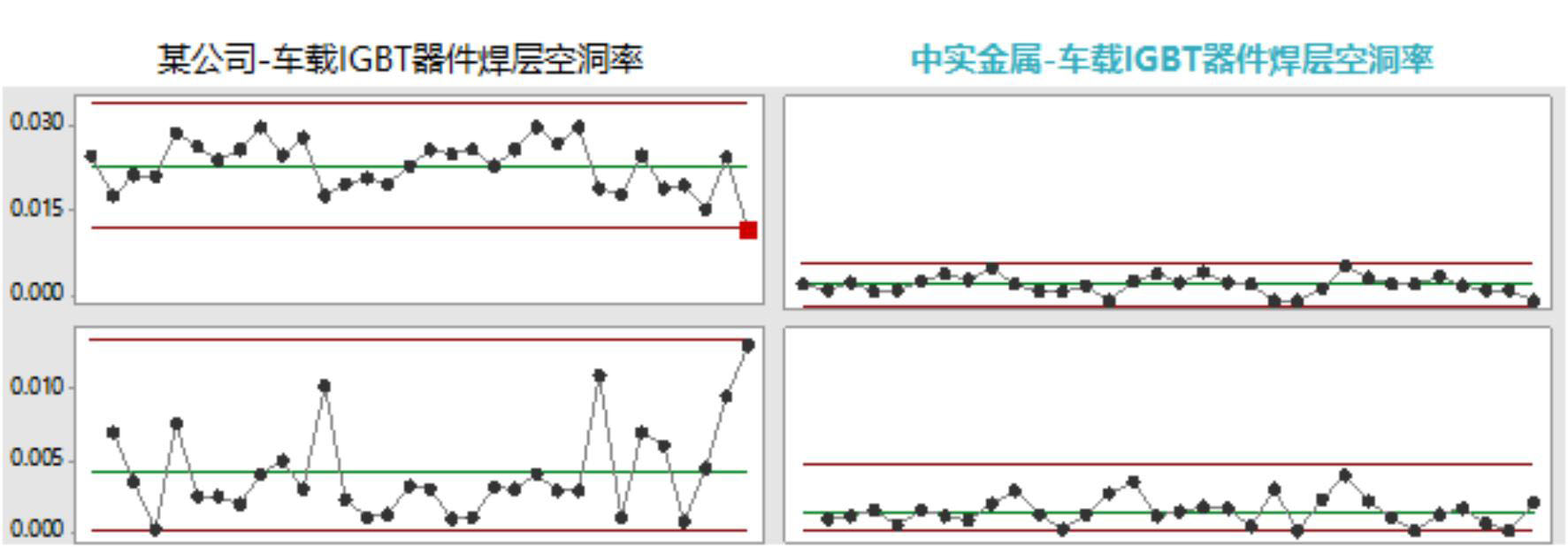

Experimental data

The following is the comparative experimental data, it can be seen that the real IGBT preformed solder effectively reduces the welding cavity rate, and the product stability performance is better.

At present, Zhongshi IGBT preformed solder has been stably supplied to major semiconductor enterprises, new energy automobile enterprises and so on.

More products, please contact us!